Call us today at (716) 807-8271

Call us today at (716) 807-8271

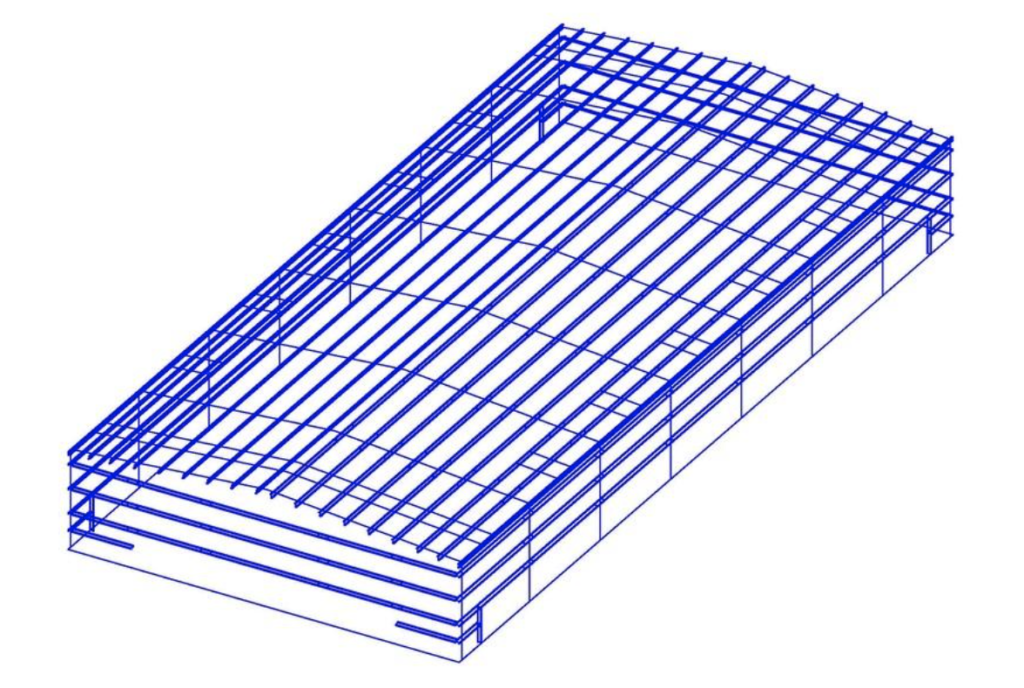

The secondary framing of a metal building system carries the loads on the surface of the building to the primary framing system. In this article, we will explore the types of secondary framing systems typical to a metal building.

Roof Purlins

The roof’s secondary members are identified as “purlins.” Purlins can be cold-formed shapes, bar-joists or 3-plate members. The most common type of purlin utilized is a cold-formed Zee member. Cee member shapes are utilized for roof openings. Purlins commonly come in 8″, 10″ and 12″ depths, however some manufacturers have slightly different offerings. The members are available in a variety of gauges typically ranging from 17-gauge to 11-gauge.

Bar-joists, also called truss purlins, are utilized when the roof loads exceed the capacity of a cold-formed purlin. For example, in Western New York the ground snow load is 50 psf. When bay spacing exceeds 30′-0, a truss purlin typically needs to be utilized. This can also occur if there is a high collateral (under hung) load requirement.

3-plate members are rarely used for the roof secondary framing. However, in very heavily loaded buildings 3-plate members can be required. 3-plate members, or traditional hot rolled beams, can also be utilized for support of heavy roof openings such as roof top units.

Eave Struts

The eave strut sits at the intersection of the roof and wall planes and must support attachment of both the roof and wall panel systems. The eave strut is most often a Cee shape that has a pitch on the top flange to accommodate the roof slope.

Wall Girts

The wall’s secondary members are identified as “girts.” Wall girts can be cold-formed, hot-rolled or 3-plate members. The most common wall girt is a cold formed Zee member. Cee members are used for a framed opening, just like in the roof. Cold-formed wall girts are available in the same depth and gauge offering as the roof purlins.

Hot rolled structural shapes or 3-plate members may also be utilized for wall girt conditions. This is often done when the covering on the walls is not metal. For example, if the exterior of the building is going to be masonry, the masonry will rely on the metal building system for some lateral support. In these scenarios, a row or two of structural members will be utilized to provide this lateral support. These members are often called spandrel beams.

Girt Conditions

The wall secondary can also vary in its relationship to the main frame members. The most common girt condition is a “bypass” condition. A bypass girt condition exists when the girts are completely outside of the building columns. Bypass girts can either be simple, meaning they will butt together at the column, or continuous, meaning they over-lap at the column. A continuous girt condition allows the girt member thickness to be lighter making it the most economical condition.

A simple girt condition is often utilized if you are going to be field locating wall openings, or intend to install openings in the future. Girts can also be “inset” meaning they are inset in relationship to the main frame. Inset girt conditions are always simple butted members. Girts can also be “flush” where the exterior face of the girt is in line with the exterior of the column.

Conclusion

Secondary framing offering may vary slightly between manufacturers, but the above summary provides a baseline understanding of the industry standard.