Call us today at (716) 807-8271

Call us today at (716) 807-8271

In our previous article “Metal Buildings 101,” we reviewed the major components of a metal building system. Here we will dive deeper into the primary framing system.

The primary framing system is the main frame of the building consisting of the columns and rafters. The columns and rafters transfer the loads directly down to the foundation system.

3-Plate Built Up Members

The columns and rafters of a metal building are typically 3-plate built-up members. To most people outside of the metal building industry, the term 3-plate built up member is foreign. Metal building manufacturers utilize plate steel that is welded together to create the custom columns and rafter shapes. This differs from conventional construction, which typically utilizes standard hot rolled structural members such as wide flange members (I-beams), tubes and channels. The 3-plate members are similar in shape to a traditional I-beam consisting of two flange members and one web member.

Columns

The most common profile utilized is a tapered column. Tapered is the most economical column design. If you do not specify, a metal building manufacturer will always default to a tapered, unrestricted column design. Columns can be straight. Straight columns can also be restricted in depth. This is often done when the interior of the space is going to receive finishes (office, retail, commercial), or there is an interior racking system. Keeping the columns straight and restricting the depth limits the impact on the interior of the space. A hybrid profile is what some manufacturers call a “supermarket column.” A supermarket column is a column that is straight up to a certain height and tapers above. Utilizing this profile, the straight section limits disruption on the interior of the space where required, and allows for economy of the tapered section where no restrictions exist. A very seldom used profile is a reverse tapered column. When a reverse tapered column is utilized, the column itself is typically outside of the exterior wall of the building and it is utilized to create an aesthetic. Interior columns can be 3-plate members, tube or pipe steel. If 3-plate members, the profile is straight.

Rafters

The most common profile is a tapered rafter. Like columns, tapered is the most economical rafter profile and the default design. Rafters can be straight and restricted in depth. They typically maintain a specific clearance inside the building. It can also be specified to create a particular aesthetic. Rafters can be “open web” like a conventional truss or joist girder. An open web rafter is often utilized for large clear span buildings. Some benefits of an open web rafter are reduced weight, the ability to run electrical/plumbing/HVAC through the rafter and increased airflow.

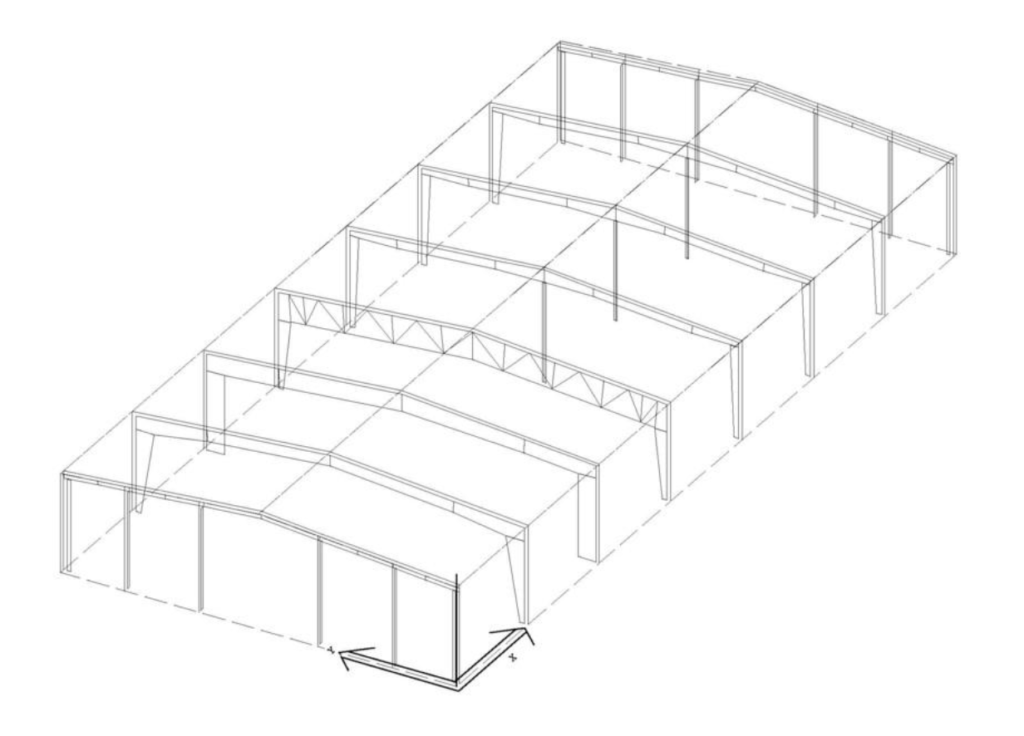

Primary Framing Systems

A rigid frame clear span has no interior column members. Clear spans can be gabled or single sloped. The use of clear span framing provides a wide open floor plan for maximum flexibility.

A modular rigid frame utilizes interior columns to provide multiple spans for wider buildings. Incorporating interior columns will reduce the overall cost of the frames. The interior column spacing can be varied to accommodate most interior floor plans.

Lean-to frames consist of one column and one rafter that ties into a main building frame.

These are the components and the major types of primary framing systems. The framing systems are standard across the metal building industry. Each manufacturer may utilize a different name, but the design is the same.